Turnkey Laboratory and Research Plants

From planning and automation to a fully operational laboratory plant with documentation – all from a single source at AP-Miniplant.

Your laboratory plant – professionally engineered and implemented

With us, you get planning, process equipment, instrumentation and automation for your miniplant from a single source.

Thanks to decades of experience in custom plant engineering for small-scale process systems and laboratory equipment, we provide tailored solutions for your specific requirements.

From Concept to Commisioning

Inquiry & Quotation

Concept Development

Detailed Planning & Customer Approval

Construction & Automation

Testing & Final Approval (FAT)

Delivery & Commissioning

Our Solutions for Your Process

Whether reaction, separation or downstream processing: we design and build laboratory and pilot plants tailored to your process. Individually configured, automated and fully tested.

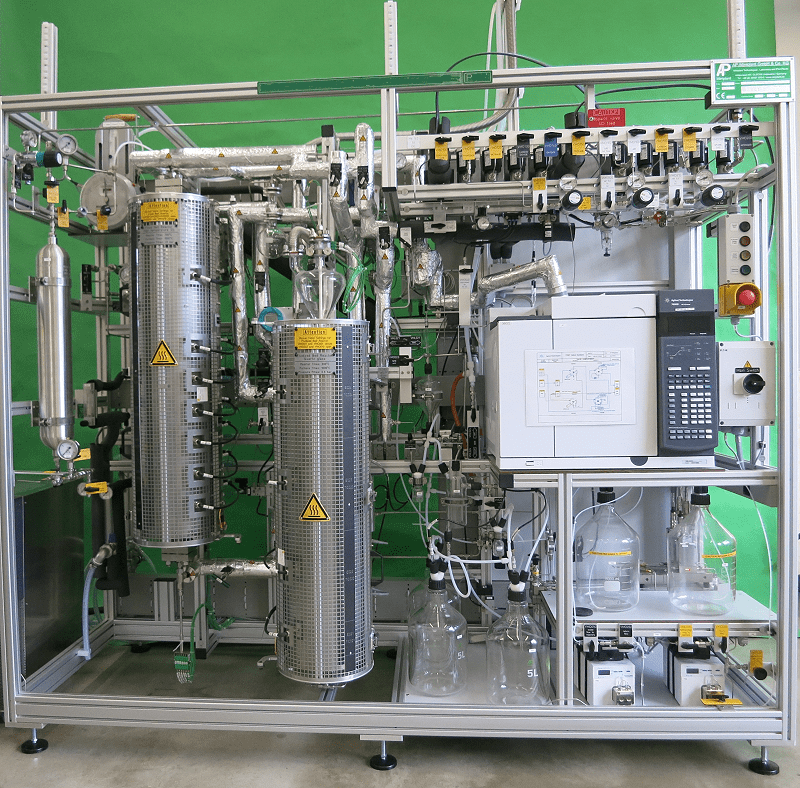

Custom-built laboratory and pilot plants

We provide fully engineered laboratory and pilot plants for the chemical, pharmaceutical and biotechnology industries – from simple stirred tank systems to complex process units.

Comprehensive service is a matter of course for us. Do you need training, spare parts or maintenance? Feel free to contact us.

Together with you, we develop customized solutions – for example for dosing very small flow rates, pumping highly viscous media or implementing advanced heat transfer concepts.

Your Benefits with AP-Miniplant

System design tailored to your process media, temperature and pressure ranges, safety requirements and project objectives.

Design, fabrication and assembly as a compact skid-mounted solution, including reliable electrical implementation in accordance with current DIN standards.

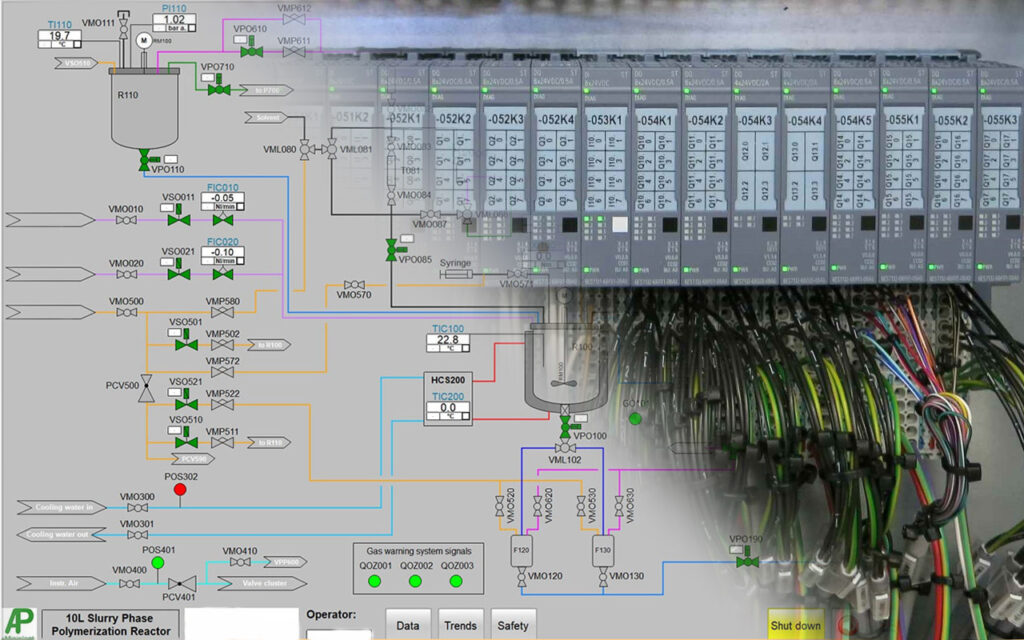

Reproducible results through structured process control, reliable automation and clear, user-friendly operator interfaces.

CE-compliant implementation, risk assessment and technical documentation integrated from the very beginning.

Project Examples from Research to Industry

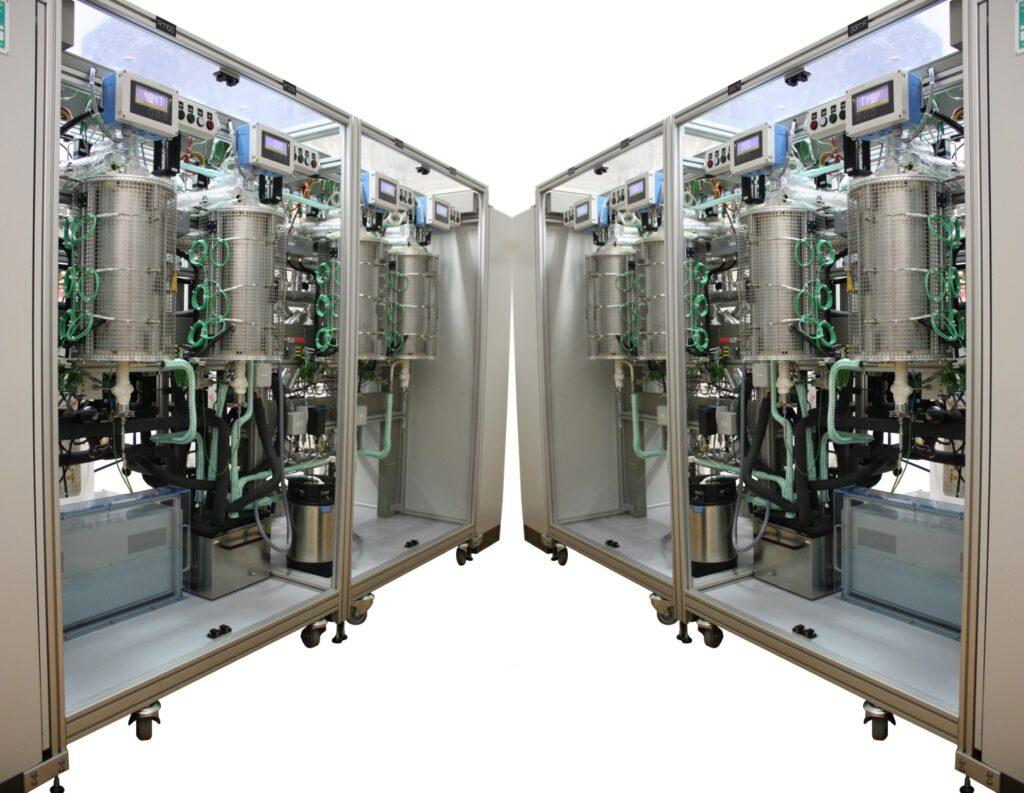

Challenge: Development of a batch system with a fluid dosing unit and two reactor trains including suspension discharge.

Plant concept: The miniplant was designed with two stainless-steel reactors (20 L and 50 L), rated for a maximum operating pressure of 14.4 bar and a maximum operating temperature of 200°C. Multiple thermostatic units and an automated dosing system enable fully automated parallel operation of both reactors. Emptying is carried out via an integrated lifting system.

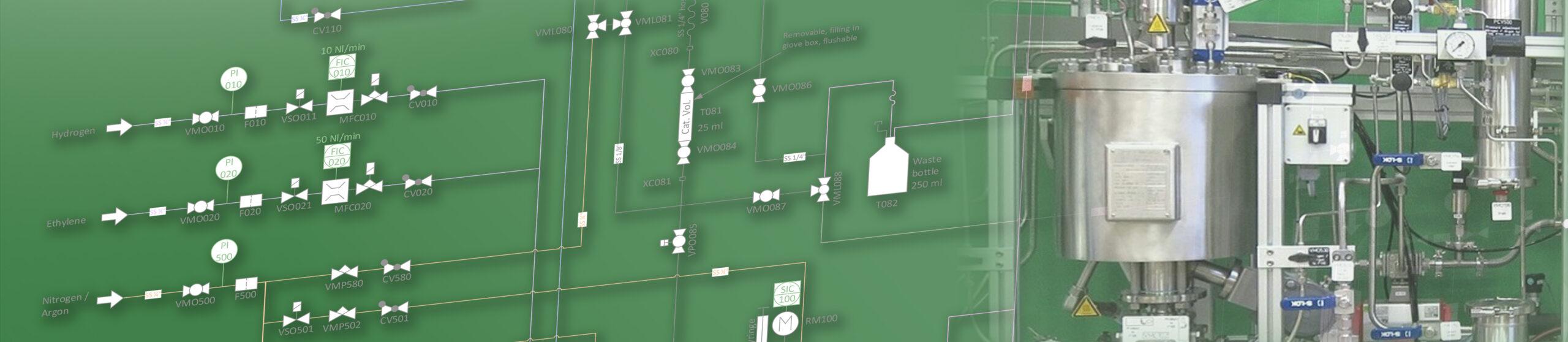

Challenge: A system for fully automated, parallel testing of monolithic catalysts at temperatures up to 1000°C.

Plant concept: Multiple reactors made from special alloys with a quartz inner tube allow operation at up to 1000°C (at atmospheric pressure) or 850°C (up to 3 bar). Ten mass flow controllers enable precise adjustment of the gas composition.

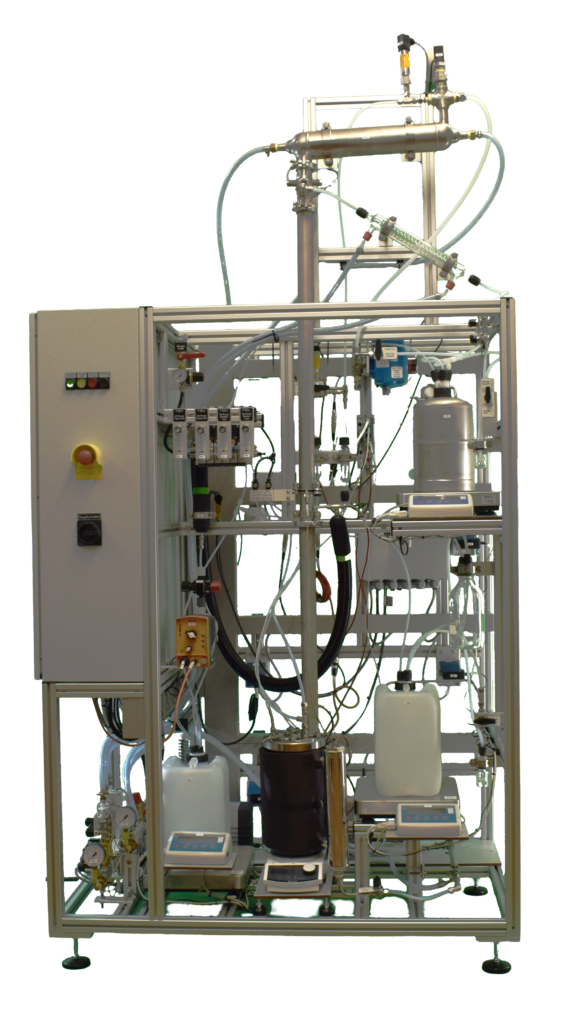

Challenge: A highly flexible distillation and rectification column with variable height for batch and continuous operation, designed for preliminary trials.

Plant concept: The system consists of a stainless-steel column, several receiver vessels, a reflux divider and a high-performance evaporator. Even in its basic configuration, this rectification column features reliable automation and well-integrated instrumentation and control systems – such as temperature sensors, pressure drop measurement and precise reflux splitting.

Proven in Demanding Industries – Trusted by our Customers

What our Customers say:

Over the different projects during the last 10 years (3 new test rigs plus revamps of them) we were always very happy to have AP-Miniplant as supplier of the complete test-rigs. During the projects we experienced a high competence level of APM and we were fully satisfied with the work done by APM. Service during the whole timeline (from first ideas until delivery and thereafter) has been and is still of high value for us and makes our daily business easier.“

AP-Miniplant – the Company

With over 30 years of experience in chemical engineering, mechanical engineering, instrumentation, fabrication and automation, we know what it takes to build reliable laboratory and pilot plants. From selecting suitable materials and complying with current standards to robust automation, we support our customers from the initial idea to a fully operational system – helping to avoid typical pitfalls early in the project.

Since 1996, we have stood for innovative solutions and individually engineered miniplants. Learn more about AP-Miniplant and the way we work.