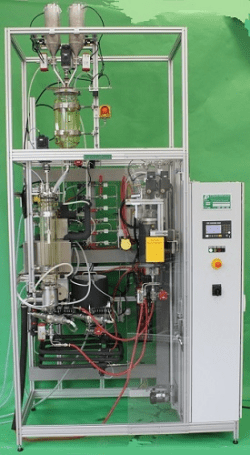

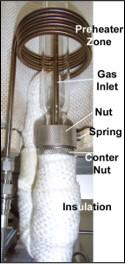

This simple fluidized bed reactor is using a specialized tubular quartz glass reactor with a high-temperature resistance of up to 1000 °C. This equipment features three different gas feeds, allowing precise control of reaction conditions. Its compact design ensures it fits conveniently into a standard laboratory fume hood.

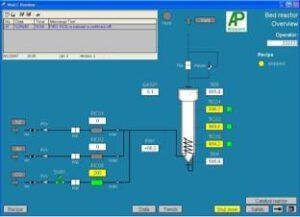

The special feature of this device is its fully automated function, which makes it a reliable and efficient tool for activating catalytic converters, for example.

Features:

- 3 gas feeds.

- Tubular quartz glass reactor (Tmax = 1000 °C) as fluidized bed reactor.

- Compact design fits into a laboratory fume hood.

- Fully automated.

- Suitable for catalyst activation.

| Description | Unit | Value |

|---|---|---|

| Dimensions L x D x H | mm | 960 x 1770 x 1100 |

| Weight | kg | 131 |

| Electrical supply | AC 220 V / 60 Hz +- 10 %, max. 3 kW | |

| Ambient conditions | 5 to 40 °C, max. humidity 90% @ 20 °C | |

| Pressure conditions | bar | -1 to 0.5 bar |

| Temperature conditions | °C | Reactor & furnace: 0-1000 °C After reactor: 0 to 200 °C |

| Reactor type | Tubular glass reactor | |

| Overpressure protection | Safety valve, opening pressure: 0.5 bar | |

| Gas supervision | CO sensor | |

| Gas supplies | Pressure 3.5 – 5 bar absolute, Gases: Nitrogen, air and carbon monoxide, total gas flow: 2500 l/h |